At Transfix, we proactively look for ways to add value for shippers in addition to moving your freight cost effectively and at superior service levels. One of the highest impact ways our team of logistics experts do this is by leveraging our proprietary data to conduct customized supply chain analyses to identify strategic opportunities to reduce costs in your supply chain.

For example, we recently helped a manufacturer with $500M+ in revenue understand key drivers of their freight spend. We surfaced the fact that the shipper was paying 20% more per spot shipment on average to deliver goods to customers who made up only 16% of their shipments as compared to their top customers.

Here are three ways you can leverage our findings to drive optimal behaviors across your own organization:

1. Segment your customers and understand freight spend by group.

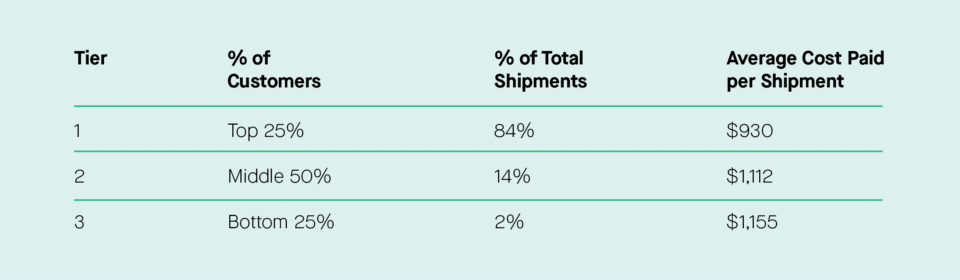

It is absolutely essential to understand how your spend varies by customer so you can develop an appropriate strategy to service your accounts. In this example, we grouped the customers into three tiers based on spot shipment count.

The top 25% customers (Tier 1) comprised more than 80% of shipments over the last six months, and surprisingly the average cost per spot shipment was actually lowest for this group of top customers. The shipper was paying a whopping 16% more to service Tier 2 customers, who represented 14% of their business and 20% more on average per shipment to ship goods to Tier 3 customers.

Once equipped with this data for your business, we recommend exploring the following:

- Negotiate pricing or evaluate a Cost + model with Tier 3 customers

- Differentiate service expectations by Tier

- Improve communication protocols between Procurement and Customer Service teams

2. Partner with customers to improve lead time.

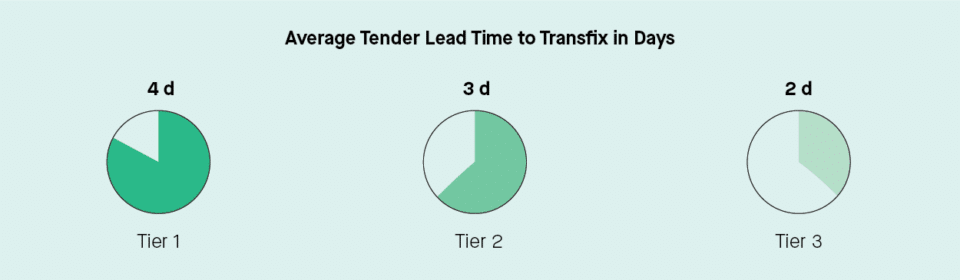

One potential driver of the higher cost to deliver goods to Tier 3 customers is lead time. The shipper had an average tender lead time to Transfix of 2 days when shipping to Tier 3 customers. This was half of the amount of time as Tier 1 customers.

Given Tender Lead Time is often a leading indicator for both service and costs, if this is also the case for your FTL freight, we suggest:

- Partnering with your customers or distribution partners with short lead times to identify ways to improve how orders are communicated

- Evaluating a pricing strategy that incentives longer lead times

3. Track average weight by shipment.

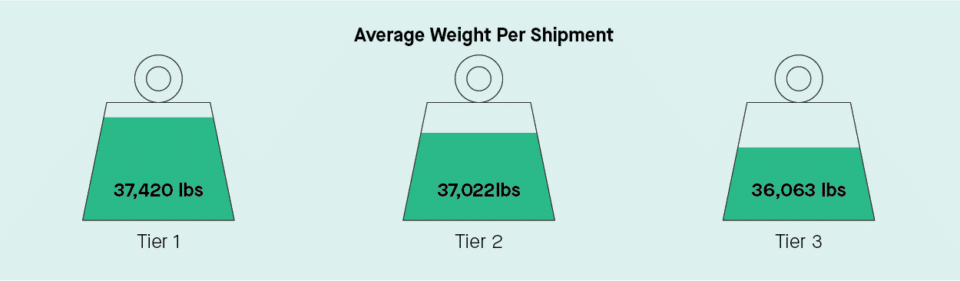

We also analyzed the average weight by shipment for this shipper and found that many of their FTL loads were being shipped with less than 38K lbs of goods on average. Furthermore, Tier 2 and Tier 3 customers, who only made up 20% of their business, had lower average weights than top customers indicating the shipper was paying more to ship less.

Once you begin tracking your average shipment weight, if they are not optimal, explore the following options to improve:

- Increase communications between Load Planning, Production, and Customer Service teams

- If possible, have your Customer Service team hold shipments for certain customers until TL is full

- Consolidate greater number of LTL shipments

If your business could benefit from a long-term partner and a customized supply chain analysis, contact us.

![[Webinar Recap] Diesel Download: A 2024 Outlook to Prepare for a Volatile Year Ahead](https://transfix.io/hubfs/iStock-1392574169.jpg)